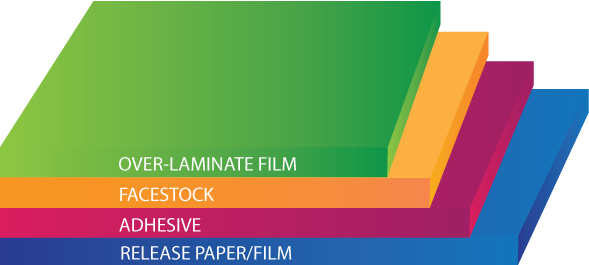

Labelstocks consist of three layers: facestock, adhesive, and release paper or film. In some cases an over-laminate film may also be applied over the facestock. Various combinations of materials offer labelstocks that satisfy a variety of performance requirements.

Transparent film that is applied over the facestock.

It protects the printed surface, prevents decolouring,

and provides a decorative appearance.

The material used as facestock are paper or film with printing coating.

It is important to select the facestock that meets all specifications,

including colour, appearance, touch, heat resistance, and water resistance,

depending upon the use and design. Lintec offers a variety of facestock including

surface-treated materials, nonwoven fabric, woven fabric, and aluminium.

The basic components of adhesives are acrylic, rubber, and silicone

and the one to choose will depend on the application. It is also necessary

to select adhesive types on whether they are to be permanent, removable,

or re-applicable.

Paper or film coated with releasing agent is termed “release paper” or “release film”.

It is used not only to protect the adhesive surface, but also functions

as liner during label manufacturing process.

Lintec carries out full process, from pulping to production of release paper/film.

A range of releasing properties are available.

Lintec has variety of UL/CUL certifed labelstocks (such as variable printing labelstocks, conventional printing labelstocks) with combination of major ink ribbons offered by various manufacturers.